Speaker

Description

The NSTX-U Recovery Project is completing the transition from the design phase to the fabrication and installation phase in the early part of 2020. The design that has been established is based on the findings of the 2017 Extent of Condition review, and includes significant technical improvements to the machine core and auxiliary systems, in order to provide a high-reliability use facility. The Project had a successful DOE baseline review in August 2019; this review and subsequent DOE authorizations included significant elements of long lead procurement, and many components are presently in fabrication. This paper will describe key technical aspects of the Recovery Project design, as well as progress towards Project completion.

A key aspect Recovery Project scope are the new inner-PF coils. Six new coils are being fabricated, based on specific design improvements relative to the previous coils. This includes the elimination of in-line braze joints and simplification of the winding pattern to ease manufacturing. An image of the first production PF-1a coil, with two of four winding layers near complete, is shown in Fig. 1 .

.

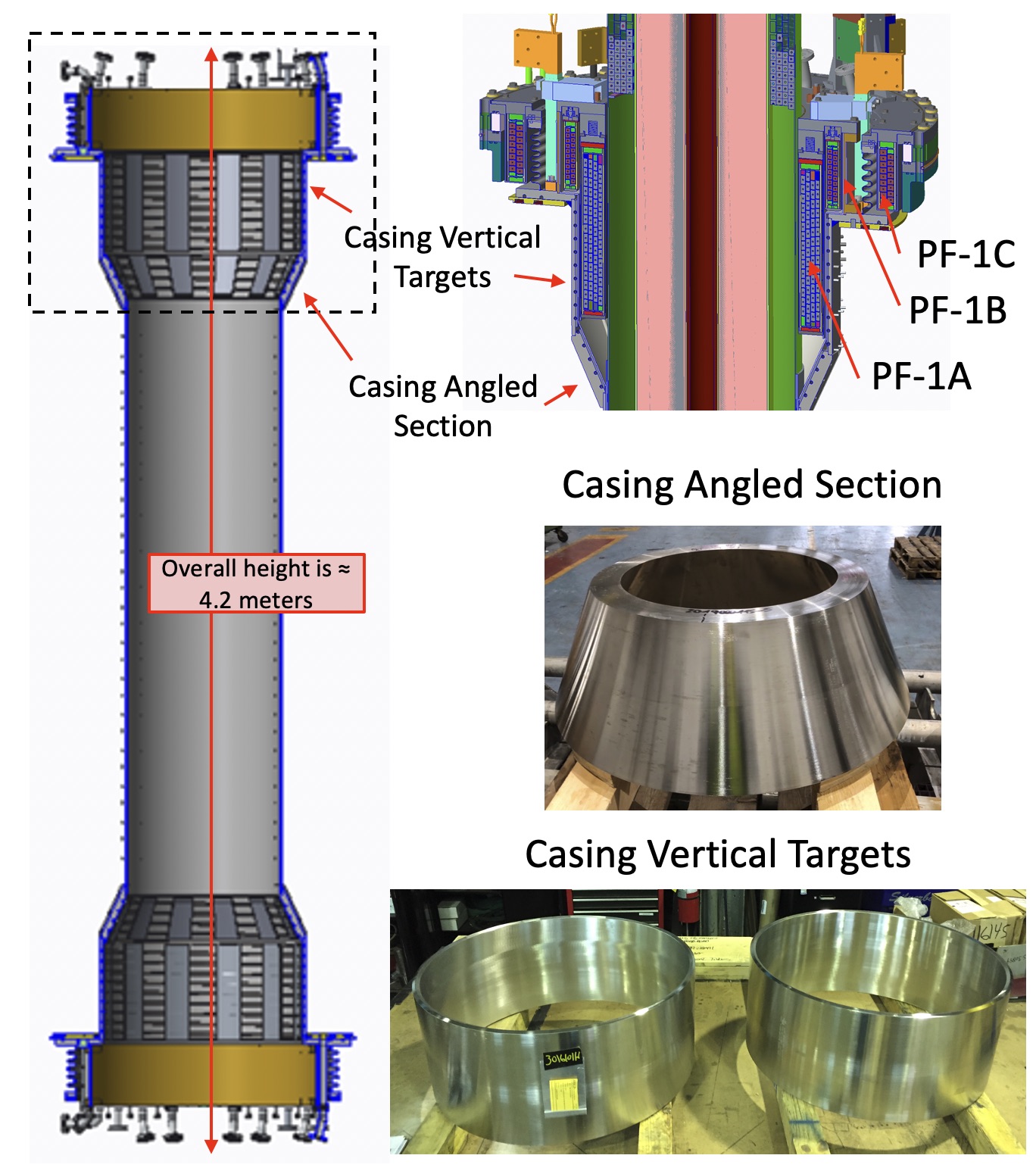

The Recovery Project is also fabricating a new Center Stack (CS) assembly to provide the inner vacuum boundary and to support the coils (see Fig. 2) . The 4.2 m tall CS casing is under fabrication, with all forgings having been completed. These will be welded and post-machined to provide the appropriate tolerances. Compared to the original NSTX-U CS casing, this component has improved weld designs, enhanced heating and cooling features to support bakeout and operations, and tolerances that support Project alignment requirement.

. The 4.2 m tall CS casing is under fabrication, with all forgings having been completed. These will be welded and post-machined to provide the appropriate tolerances. Compared to the original NSTX-U CS casing, this component has improved weld designs, enhanced heating and cooling features to support bakeout and operations, and tolerances that support Project alignment requirement.

The new CS assembly also includes numerous other new features shown in Fig. 2. The PF-1a and PF-1b coils are preloaded in Inconel 718 slings; this preload provides mitigation of thermal stresses due to water cooling after the pulse. Double O-ring seals are used at each of the primary vacuum interfaces, reducing both the likelihood of major leaks and the level of permeation.

Other key fabrication elements of the machine core scope have started, including:

• New plasma facing components are being fabricated for the CS casing and all divertor regions. In high heat flux regions, these utilize fine-grain isotropic graphite, are castellated to reduce the thermal stresses, and have “fishscaling” to eliminate leading edge heating.

• NSTX-U utilizes in-vessel passive stabilizing plates to reduce the growth rates of instabilities such as VDEs and RWMs. These plates have large loads during disruptions, and the Recovery Project is implementing improved welds and brackets to counteract these forces.

• The outer PF coils are being realigned to meet stringent error field requirements.

A major component of Recovery scope involves improving the neutron shielding of the NSTX-U test cell. A new concrete labyrinth wall was poured at the primary test cell entrance, and roof blocks were fabricated (See Fig. 3) . Additionally, many penetrations in the test cell walls are being filled with grout, neutron putty, or polyethylene sheets.

. Additionally, many penetrations in the test cell walls are being filled with grout, neutron putty, or polyethylene sheets.

The Recovery Project is implementing a new Personnel Safety System (PSS). This includes a set of configuration managed safeguards against contact hazards, a trapped key system for managing the facility configuration, and a new IEC 61511 compliant access control system using a safety-class PLC. These systems will significantly enhance the operational safety of the facility.

The Recovery Project is making rapid progress, with first plasma scheduled for the summer of 2021.

This work was supported by U.S. DOE Contract D-AC02-09CH11466 and DE-AC05-00OR22725. The project appreciates analysis support provided by Oak Ridge National Labs.

| Affiliation | PPPL |

|---|---|

| Country or International Organization | United States |