Speaker

Description

The challenge

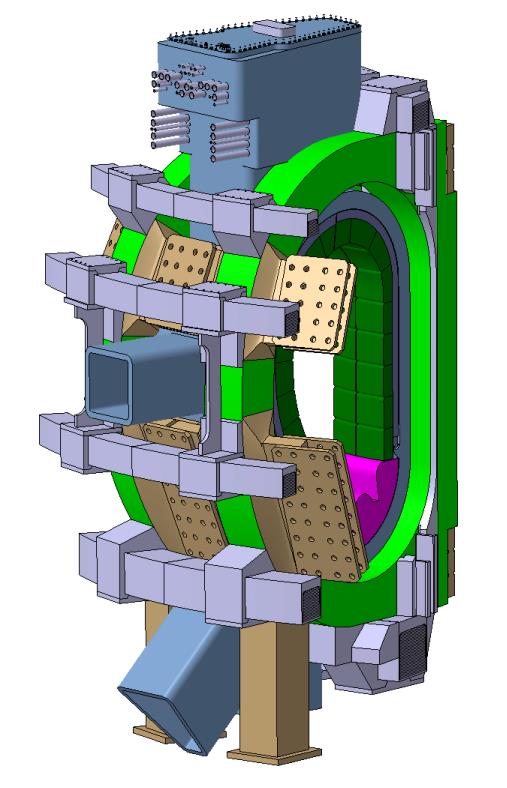

A power plant based on a tokamak architecture has a magnetic cage with thick shielding, so maintenance needs to be conducted through long narrow access ports (see figure 1). This means unprecedented dexterous handling of massive flexible components, which is difficult, slow and expensive. For this reason, industrial plant to date has always been arranged to allow the heaviest lifting to be done from above by a crane.

Power plants also need to achieve higher availability than has been achieved with existing experimental machines. This drives the need for simple and robust maintenance schemes on maintenance-compatible plant architecture. This makes maintenance design driving, which is why it must be understood early in the plant design.

Examples of design driving maintenance considerations are the segmentation of the in-vessel components and the layout of the pipework, components and transport corridor in the ports. These aspects are critical to maintenance, but the choice also impacts the design of the components and indeed the layout of the whole machine and ex-vessel systems.

The size and mass of the in-vessel components for DEMO are significantly higher than for existing machines, including ITER, and the radiation and temperature will be even more challenging. This means DEMO will require novel maintenance solutions and technologies with a different power plant architecture to existing machines. The ITER approach of assembling in-vessel maintenance equipment and handling a high number of components is not appropriate for DEMO and would not be able to meet the plant availability requirements. The same is true for the JET approach of performing all maintenance operations using booms deployed through equatorial ports.

However, there is a large technology overlap with ITER and with wider industry and this will be used wherever possible because of the cost savings, the reduction in technical risk, the data and demonstrated reliability and it is important to standardise the remote maintenance systems as far as possible to reduce the time and cost of design and testing. This applies to the handling systems and movers, but also to the tools and all the interfaces, including handling, mechanical attachment, electrical, signal and fluid (pipes).

Where there is no technology overlap, novel solutions and enabling technologies must be developed to meet the powerplant requirements. There is significant technical risk associated with enabling technologies that are essential to the chosen architecture because if the requirements cannot be achieved then changes to the architecture would be required. The technical readiness level for these enabling technologies must be increased in step with the developing design, to maintain an acceptable risk level. Examples of these enabling technologies for DEMO include the in-bore cutting and welding that is required for the closely grouped pipes on the plasma facing components (breeding blankets and divertor cassettes), and the dexterous handling systems for the massive breeding blankets and divertor cassettes.

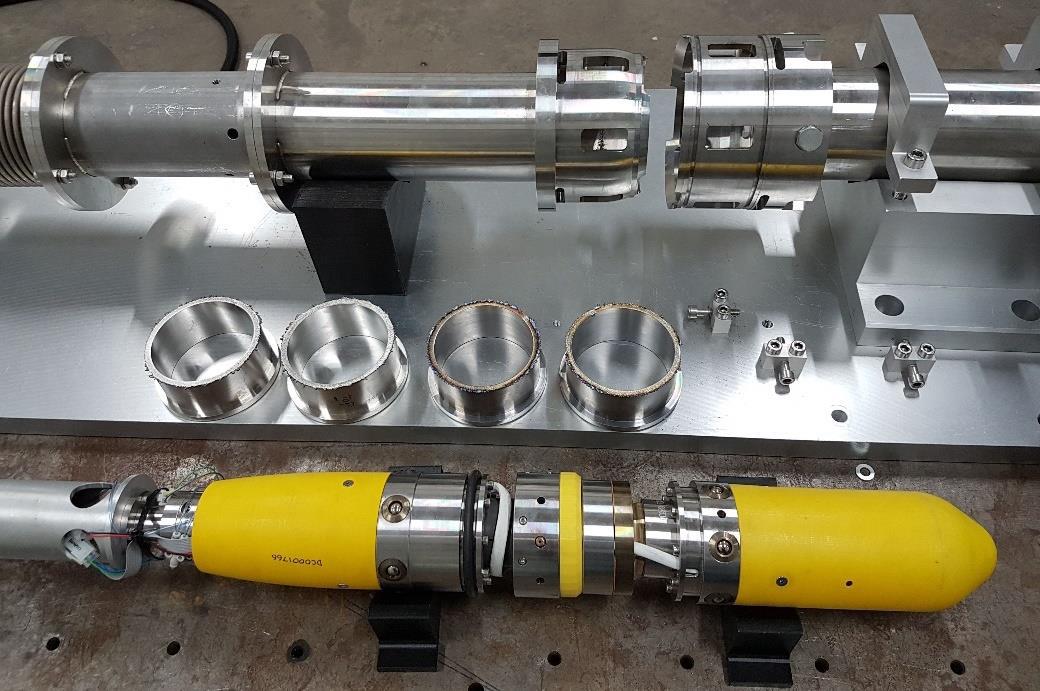

In-bore cutting and welding

The EU has been developing miniature laser cutting and welding tools (see figures 2 and 3) that can be deployed down the bore of pipes to demonstrate the feasibility of the enabling technology [1., 2.]. Laser has the advantages of speed, and, as a non-contact process, it has better recovery and rescue options than existing technologies, such as TIG arc welding. Initial trials have been successfully conducted on proof-of-principle tools. However, further development is required to increase the laser power and ultimately to produce a qualified weld process.

Trials have also been conducted on pipe alignment (see figure 4) and tool deployment (see figure 5) which have shown that the alignment forces are high and would be very challenging for the pipe handling systems. Further work is required to develop an alignment system that is less demanding of the handling system.

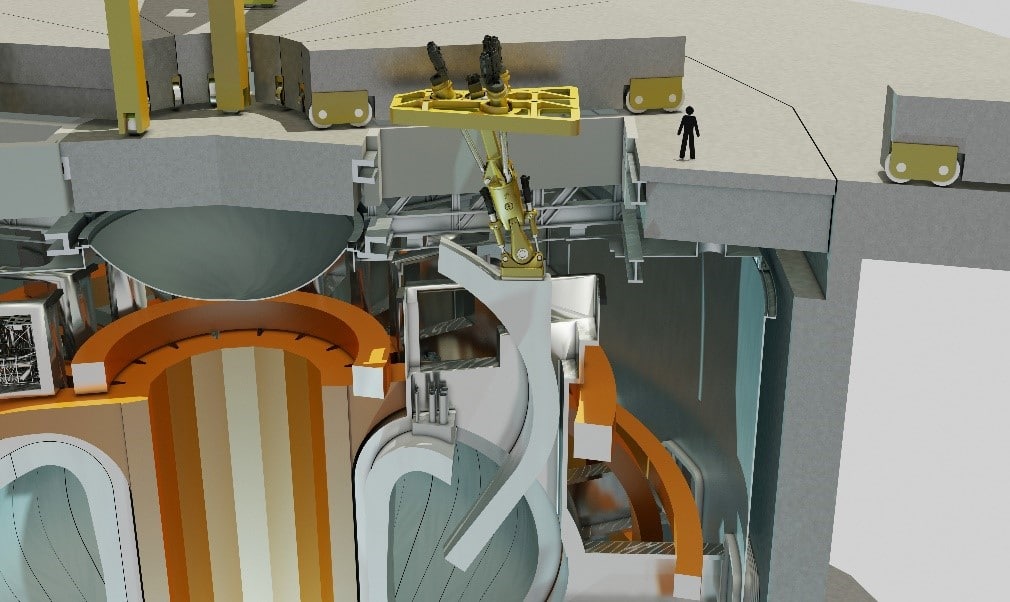

Dexterous handling of massive components

The layout of DEMO requires a mover that can fit in the port and dexterously handle the in-vessel components that can weigh up to 80 tonnes. A design has been produced for a blanket handling system (see figure 6) but it has limited reserve factors on the working loads, cannot sustain the seismic load case and the stiffness and dynamic performance of the mover would make it difficult to control, leading to very slow operation and lack of accuracy.

New work is starting on the maintenance systems for different tokamak configurations that have split blankets and a double-null. The design process requires time intensive iterations between design tools such as structural analysis, kinematic evaluation and the dynamic and control models. Work is underway to allow these tools to communicate directly with each other and ultimately to integrate them into a single tool. This virtual engineering will allow much more rapid development and optimisation to support the evolving plant design.

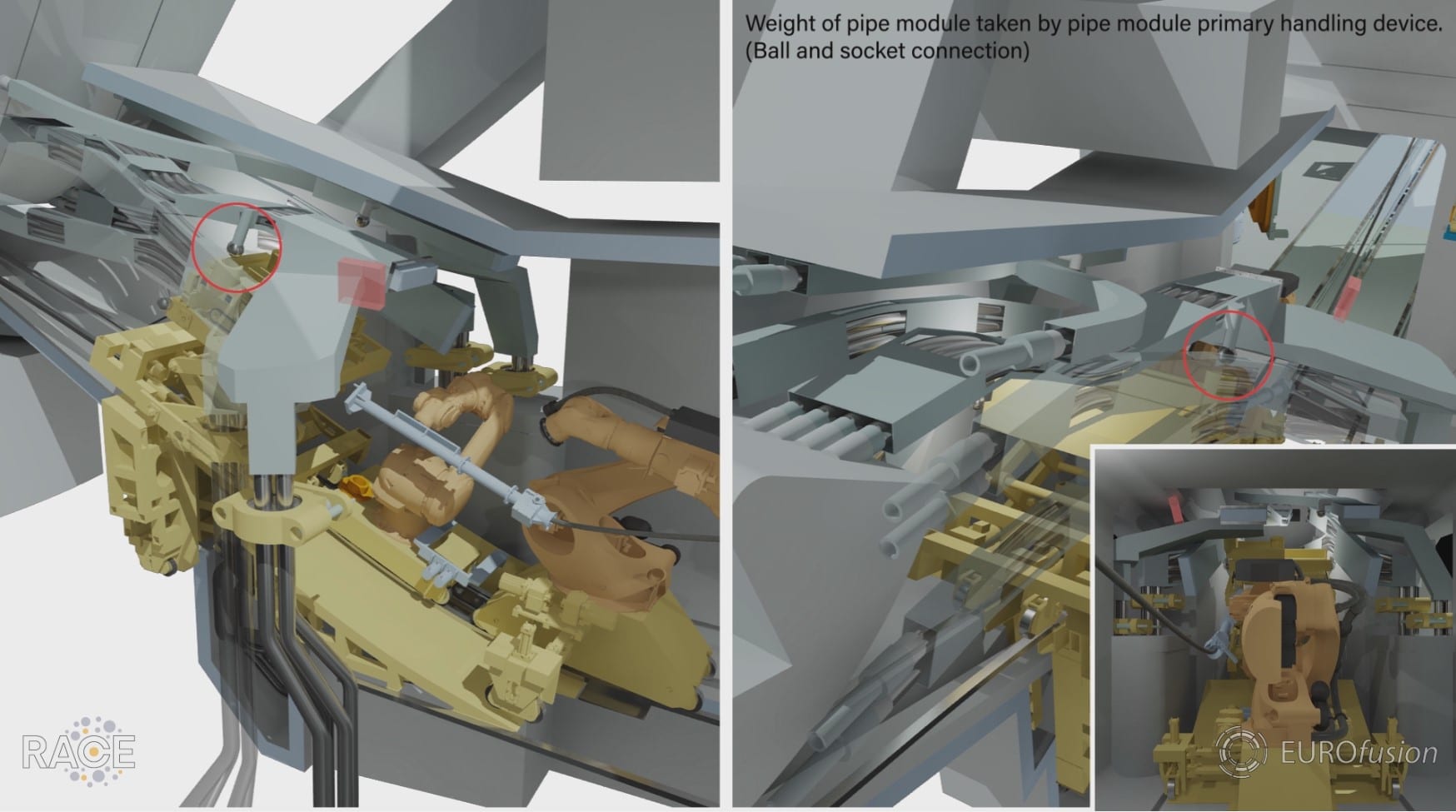

Port layout

The layout of the port is also critical to the plant design. It is difficult to arrange all the components and services in a way that they can be maintained whilst retaining the transport corridor for the large plasma facing components that must be transferred out of the vessel. Work on DEMO has shown that modified industrial handling equipment can be used for maintenance. For example, robots, slideways and scissor lifts. This means the technology risk is low, but the integration risk remains high and the layout of the equipment is critical to success. A small change in the pipe layout can make it unmaintainable. A model of the port layout has been created to enable the visualisation required to create the maintenance strategy and design the equipment, and this has been animated to show the sequence of operations and communicate the constraints to the plant designers (see figure 7).

Looking ahead

The technical risks inherent with the novel maintenance solutions required for a fusion power plant have been well recognised across the world. In the EU, a seven-year programme has been proposed to analyse the maintenance implications of the EU DEMO plant design to enable plant option down-selection and to develop the enabling technologies that are not available from industry or ITER.

The focus of the programme is to develop the design of remote maintenance equipment integrated with the plant design, to reduce or remove key risks. Within this programme, designs are required to allow feasible maintenance of the breeder blankets and other in-vessel components. As the system designs become more detailed the programme will produce proof-principle equipment to validate designs and virtual engineering tools to reduce the key technical risks.

This work has been carried out within the framework of the EUROfusion Consortium and has received funding from the Euratom research and training programme 2014-2018 and 2019-2020 un-der grant agreement No 633053. The views and opinions expressed herein do not necessarily reflect those of the European Commission.

References

[1.] “Service Joining Strategy for the EU DEMO”, T. Tremethick et al, ISFNT-14 (2019).

[2.] “Laser cutting and welding tools for use in-bore on EU-DEMO service pipes”, K. Keogh et al, Fusion Engineering and Design, volume 136, part A, November 2018, pages 461-466.

| Affiliation | UKAEA |

|---|---|

| Country or International Organization | United Kingdom |