Speaker

Description

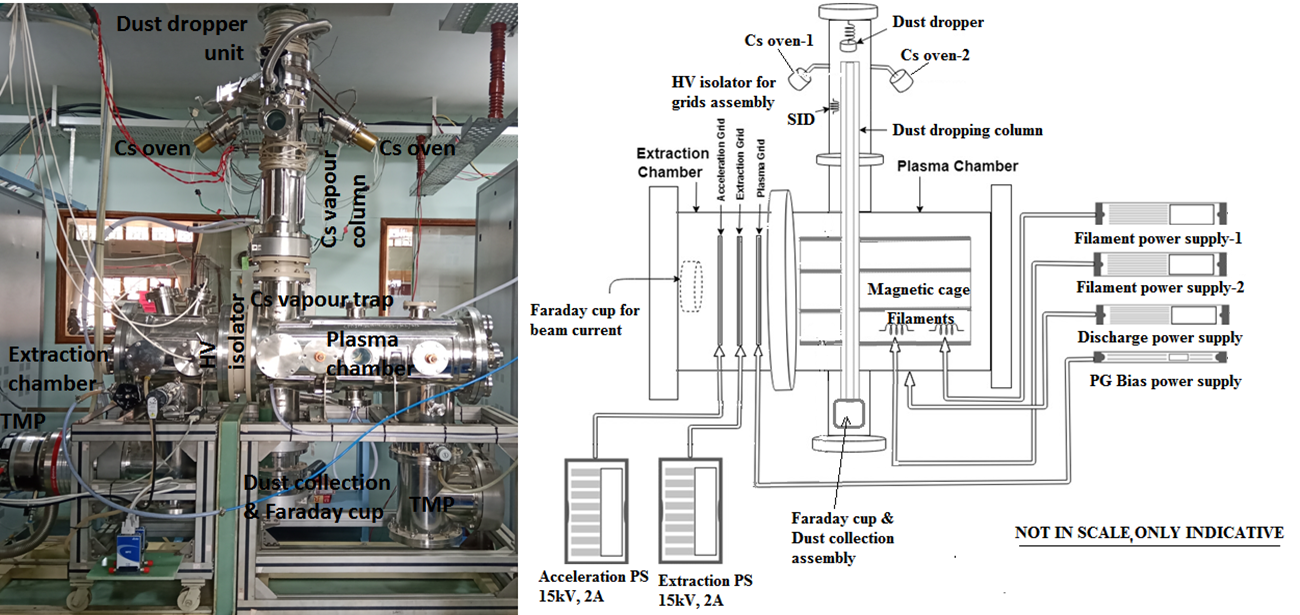

A negative hydrogen ion source based neutral beam injector system (NNBI) is an important auxiliary heating and current drive system for ITER-like fusion reactor machines. Cs vapour injection into a negative hydrogen ion source is inevitable to achieve higher negative ion production yield through surface process mechanism on a low work-function surface. However, the introduction of Cs vapour into the ion source volume is associated with multiple issues related to Cs inventory and corresponding maintenance. Cs vapour is injected into the source volume by a single or multiple nozzles based Cs delivery system, kept at high temperature (~ > 200oC). High Cs consumption is observed in all the present-day fusion grade negative ion sources to maintain fresh Cs coverage to overcome sputtered wall material or Cs compounds formed by the impurities. Due to high Cs inventory, Cs pollution within the accelerator stages triggers breakdowns and also increases the maintenance frequency. In this report, a novel surface assisted volume negative ion source is described from concept level to plasma experiment 1 including the engineering design of the beam extraction system. The whole experimental system 2 is established at CPP-IPR, another R&D center of IPR in Assam, India. It is a proof-of-principle experiment that addresses issues of, Cs pollution in the ion source chamber and higher localized scalable surface to volume ratio near the beam extraction zone in the plasma without modifying the ion source geometry. The experimental setup and its schematic internal components are shown in fig.1.

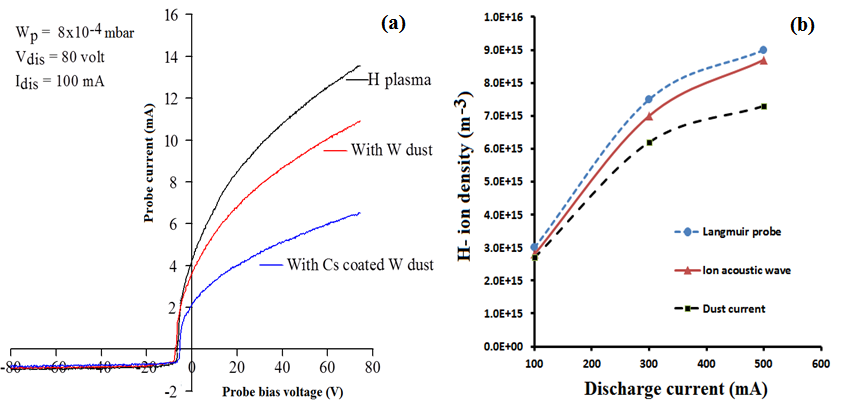

Negative hydrogen ions are formed copiously on Cs coated micron-sized tungsten (W) dust, sprinkled in a controlled manner from a Cs coating unit (CCU), installed vertically over the filament discharge type ion source plasma chamber. The plasma is confined in a multi-cusp region. The plasma grid in the extraction system is closely placed near the Cs coated dust falling plane. The cylindrical tower-shaped CCU comprises of a W dust dropper, two Cs ovens for injecting Cs vapour into the coating unit, chamber-wall heating and cooling arrangement for Cs recycling and trapping, a Cs trap near the interface zone between the plasma chamber and the CCU to prevent Cs leakage into the ion source plasma chamber, a surface ionization detector (SID) based Cs vapour density monitoring unit and a laser scattering unit for dust density measurement. Due to this Cs trapping scheme, the probability of Cs pollution in the plasma source and within the accelerator stages is negligible and confirmed by spectroscopy. The present source has the advantage to improve the surface to volume ratio further by changing the dust density without changing the ion source geometry. The negative ion fraction is measured using three different diagnostics, which are Langmuir probe (LP), Ion acoustic phase velocity, and dust current measurement techniques. Plasma parameters are measured by an LP and OES. Dust current is measured by a specially designed faraday cup connected to a sensitive electrometer. The negative ion fraction measured by all the above techniques lies within 0.1–0.3 (i.e. 10%–30%) w.r.t. the plasma density. Plasma density obtained is in the range of ~ 1–4×1016 m-3 for discharge current 100 – 400mA, correspondingly plasma temperature lies within 0.8 – 1.2eV. Typical probe characteristics and corresponding measured negative ion density, by three different diagnostic techniques are shown in fig.2. In-situ recycling of the accumulated dust is an engineering issue in the system and needs to be addressed in the future.

Acknowledgment:

Authors have deeply acknowledged and remembered the contribution of Prof. P. K. Kaw, starting from the inception of the idea to the 1st publication.

References:

1. B. Kakati, S. S. Kausik, M. Bandyopadhyay, B. K. Saikia & P. K. Kaw, “Development of a novel surface assisted volume negative hydrogen ion source”, Scientific Reports, 7: 11078, (2017) and its references.

2. B. Kakati, S.S. Kausik, B.K. Saikia, M. Bandyopadhyay and P.K. Kaw. Indian Patent “A process for production of a negative hydrogen ion and apparatus thereof”. Publication Date (U/S 11A): 24/07/2015.

| Affiliation | Institute for Plasma Research (IPR), HBNI, Bhat, 382428, Gandhinagar, India. |

|---|---|

| Country or International Organization | India |