Speaker

Description

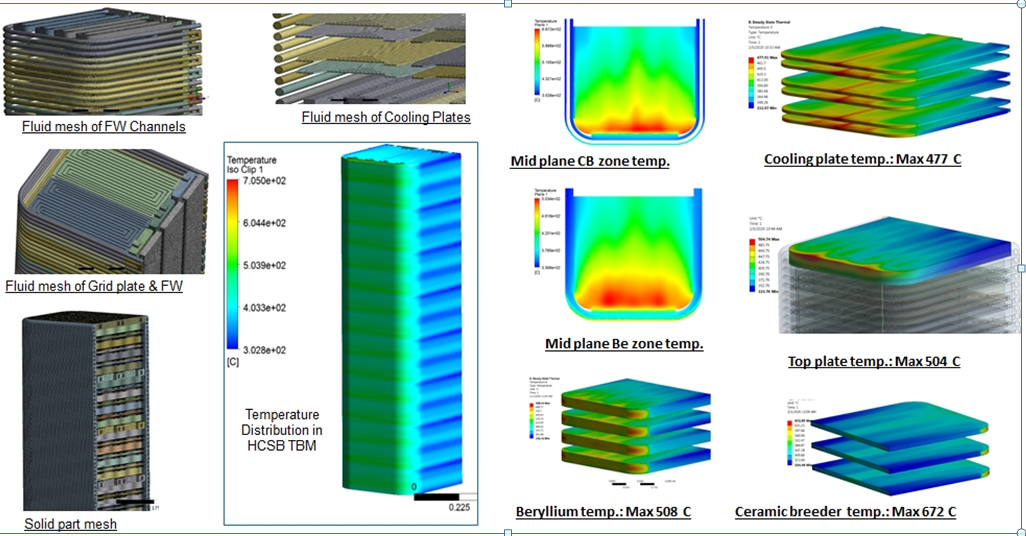

ITER Council has decided to reduce the number of port from three to two for testing TBM due to the introduction of a Disruption Mitigation System during November 2018. Since then, India is proposing Helium Cooled Solid Breeder (HCSB) concept to be tested in one half of the two ports available for the same in ITER. Indian HCSB concept is having Reduced Activation Ferritic Martensitic Steel (RAFMS) as the structural material and Lithium Meta Titanate (Li2TiO3) and beryllium as the tritium breeder material and neutron multiplier respectively. Based on the neutronic analysis which ensures the adequate tritium-breeding ratio (TBR), the design of the edge-on configuration of HCSB blanket has been optimized by doing extensive thermal–hydraulic, CFD analyses thermo-mechanical analyses including high pressure coolant loads, electromagnetic, seismic load conditions in compliance with ITER safety requirements and guidelines 1. Some the analysis results of the optimized HCSB blanket are shown in fig. 1. Transient thermal analysis has also been simulated for the ITER transients. Results obtained from steady state and transients show that the maximum temperature of all materials are well within their limiting values. Various option of breeder modules like flaring in radial direction, comparisons of radial-toroidal and poloidal-toroidal modules and their advantages have been studied in detail in our earlier works 2

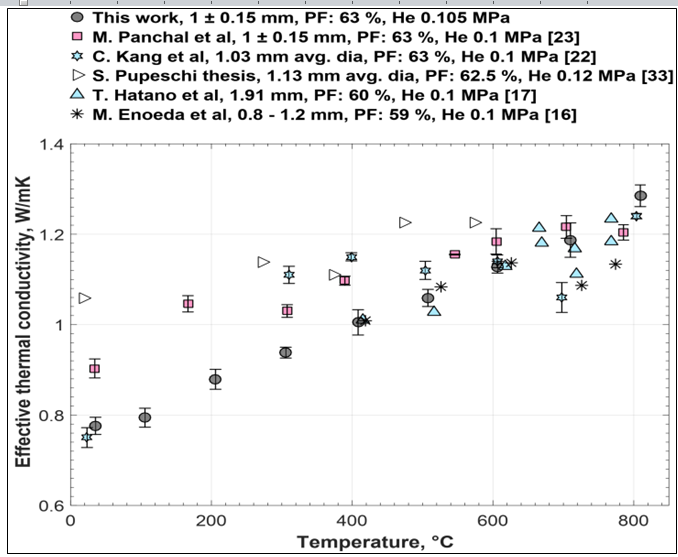

The Indian blanket related R&D program is focused on the development and characterization of different functional (Li2TiO3, Be, PbLi etc.) and structural materials, tritium technologies and fabrication technologies for the blanket module. The results from these R&D activities are being used for the design and development of various subsystems of HCSB blanket module. The spherical form (pebble) of ceramic breeder material (Li2TiO3) and beryllium multiplier are kept as a packed bed in the breeder module. The fabrication process of these materials will have the challenge to meet the demands of having suitable compositions, properties and their functional requirements. At every stage of the preparation, various characterizations on pebble and pebble bed are performed to meet the desired properties required for fusion blanket. Density and temperature dependence thermal conductivity shows the influence of porosity on the thermo-mechanical properties (crush strength and thermal conductivity) of Li2TiO3 pebbles. A test facilities for the measurement of effective thermal conductivity (Keff) of the pebble bed using steady-state Axial and transient hot-wire method have been designed and built indigenously at IPR. Fig. 2 shows the measured Keff value of Li2TiO3 pebble bed under Helium gas and compared with available literature results [4].

The Indian blanket related R&D program is focused on the development and characterization of different functional (Li2TiO3, Be, PbLi etc.) and structural materials, tritium technologies and fabrication technologies for the blanket module. The results from these R&D activities are being used for the design and development of various subsystems of HCSB blanket module. The spherical form (pebble) of ceramic breeder material (Li2TiO3) and beryllium multiplier are kept as a packed bed in the breeder module. The fabrication process of these materials will have the challenge to meet the demands of having suitable compositions, properties and their functional requirements. At every stage of the preparation, various characterizations on pebble and pebble bed are performed to meet the desired properties required for fusion blanket. Density and temperature dependence thermal conductivity shows the influence of porosity on the thermo-mechanical properties (crush strength and thermal conductivity) of Li2TiO3 pebbles. Test facilities for the measurement of effective thermal conductivity (Keff) of the pebble bed using steady-state Axial and transient hot-wire method have been designed and built indigenously at IPR. Fig. 2 shows the measured Keff value of Li2TiO3 pebble bed under Helium gas and compared with available literature results 3. India specific RAFM steels (IN-RAFMS) has been produced for the structural material of HCSB blanket. The final composition of IN-RAFM steel has been decided with varying tungsten and tantalum content. The 9Cr-1.4W-0.06Ta wt% RAFMS is found to show better impact properties than other RAFM steel heats [4]. Various thermo-physical and thermo-mechanical properties of IN- RAFMS material have been studied for the generation of material qualification database as per ITER requirement. Further R&D needs to be done for the material properties database up to the radiation damage expected in ITER (> 1 dpa).

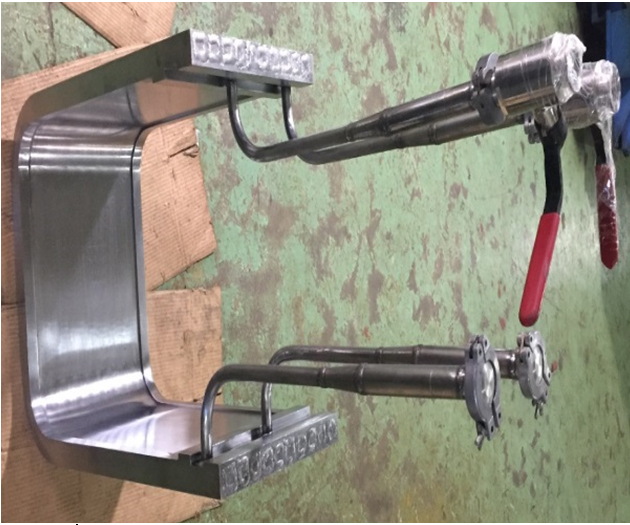

A FW mock-up having 10 cooling channels as shown in fig. 3has been successfully fabricated using modified 9Cr-1Mo steel which has similar properties of RAFM and successfully tested in high heat flux (HHF) facility using high temperature, high pressure helium loop (HELOKA) at KIT Germany. The mock-up has been tested for both normal and accidental operating conditions of ITER surface heat fluxes. The experimental results of maximum and average front surface temperature of the mock-up shows a good agreement with the FE simulation within the variation of ±2%, which is within the uncertainty margin except for some local hotspots [5]. The FW temperature for LOFA condition for 25% flow and for NO flow conditions are also within the allowable margin of deviation. Similar to HELOKA loop, the installation of an Experimental Helium Cooling Loop (EHCL) is in progress at IPR.

In summary, over the last few years, the joint team comprising of IPR and other Indian institutes has made significant progress in development of materials, fabrication technology, conceptual design, engineering design and various R&D areas relevant to TBM system development. This paper will presents the design optimization and analyses of HCSB blanket and current status of different R&D developments which provides a roadmap for the future activities planned in realizing Indian HCSB TBM for testing in ITER.

Key words: HCSB, Blanket, thermal-hydraulics, Li2TiO3, pebble bed

References:

1 D. Sharma et. al., “Design and analysis of manifolds for Indian HCCB blanket module”, Fusion Engineering and Design 129, (2018), 40–57.

2 Paritosh Chaudhuri et. al., “Comparative studies for two different orientations of pebble bed in an HCCB blanket”, Plasma Sci. Technol. 19 (2017) 125604.

3 M. Panchal et. al., “Measurement of effective thermal conductivity of Li2TiO3 pebble bed by transient hot-wire technique”, Communicated in Fusion Engineering and Design.

[4] A N Mistry et. al., "Status of India-specific Reduced Activation Ferritic-Martensitic steel and fabrication technologies development for LLCB TBM", Fusion Engineering and Design 125, (2017) 263-268

[5] S. Ranjithkumar et. al., “Performance assessment of the Helium cooled First Wall mock-up in HELOKA facility”, Fusion Engineering and Design 150 (2020), 111319.

| Affiliation | Institute for Plasma Research |

|---|---|

| Country or International Organization | India |