Speaker

Andrei Shadrin

(Bochvar Institute)

Description

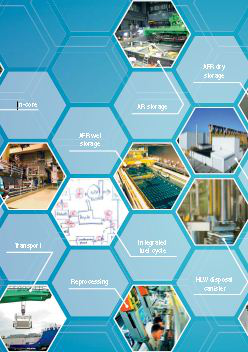

BREST-OD-300 is pilot demonstration lead-cooled fast reactor fuelled with mixed nitride uranium-plutonium fuel (MNIT). Nuclear fuel cycle with BREST reactors concept implies that the fuel has an burn-up about 10 % h.a.. “Equilibrium” isotopic composition of fissile materials (FM) fuel is used in the nuclear fuel cycle and the duration of the external fuel cycle does not exceed one year. It means that within one year spent nuclear fuel (SNF) should be reprocessed and fresh MNIT-fuel should be fabricated from the products of the reprocessing. At the present time a carbothermic synthesis technology is chosen as a basic process for the fabrication of mixed uranium-plutonium powders and pellet technology – for fuel fabrication. Thus manufacture on reprocessing of MNIT SNF from BREST reactor should provide reprocessing of fuel with cooling time not exceeding one year, FM content of 10-15%, burnup about 10% h.a. and obtain a mixture of actinides with coefficients of purification about 1000000.

It is clear that requirements for reprocessing of MNIT SNF are imposed, such as safety level, ecological issues, and economic competitiveness. In our opinion PH-process (combined (pyro+hydro) technology) of reprocessing SNF can meet all these requirements. PH-process consists of a combination of pyrochemical, including pyroelectrochemical, head operations and hydrometallurgical operations for refining of end product (U-Pu-Np-Am) and waste treatment. Development of PH-process has been run since 2011 by RIAR, Bochvar Institute, and Khlopin Radium Institute.

By now following basic technological operations have been tested in laboratory conditions on real products:

- steel cladding removal by dissolution in molten zinc;

- pyroelectrochemical recovery of uranium, plutonium, and neptunium;

- extraction refining of uranium, plutonium, and neptunium;

- separation of rare earth elements and transplutonium elements;

- separation of americium and curium;

- preparation of mixed oxides of actinides by microwave denitration;

- decomposition of ammonium nitrate and complexions.

In 2014 manufacturing of experimental setups to test engineering solutions for equipment for pyroelectrochemical operations was started and installation for inspection innovative systems for hydrometallurgical operations was completed. In 2015 design of reprocessing MNIT SNF and waste treatment facility was started. Reprocessing unit will be located at the same site with the pilot demonstration power complex with BREST-OD-300 reactor on the territory of SCC (Seversk).

Country/ int. organization

Russia / Bochvar Institute

Primary author

Andrei Shadrin

(Bochvar Institute)

Co-authors

Dr

Konstantin Dvoeglazov

(Bochvar Institute)

Dr

Valentin Ivanov

(Bochvar Institute)