Speaker

Description

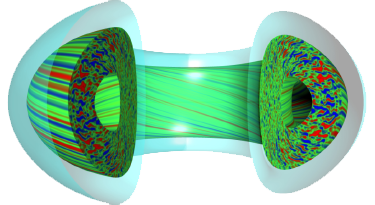

Tokamak wall protection systems are becoming a key asset for fusion machine operation, as internal plasma facing components (main wall, divertor) have evolved to high-tech actively cooled metallic walls. Tokamak (and Stellerator) walls are the thermal power sink, transfer 10-100 MW to the cooling system and heat up to temperatures of 1000-2000 K during plasma operation. These protection components are among the hottest high-tech industrial components operating in steady state, along with aircraft engine turbine blades and industrial furnaces. Operation incidents or unstable plasma events may cause abnormal hot spots on the wall, which can evolve to a component damage with potential consequences on machine availability. Wall protection systems use real-time infrared (IR) monitoring of the wall temperature, visible imaging systems, data streams relevant to the thermal event classification and expert knowledge. An active wall monitoring system uses real-time analysis of video streams, capable of recognizing known temperature patterns (strike lines, heat losses, especially from additional heating systems, uncooled or deteriorating components) as well as new thermal events, which might be significant for operational safety. The large amount of data is processed through computer vision, pattern recognition algorithms and advanced classification and management tools.

At WEST, CEA's tungsten steady state tokamak, an active wall monitoring system is being developed and progressively put in service [1]. Activities in the field of IR video data processing encompass the:

• Use of artificial intelligence and machine learning techniques for relevant event detection and classification processes,

• Development of a database of thermal events on fusion devices walls. This database is a rationalized ground truth description capturing experts knowledge,

• Computerized tools providing expert assistance for thermal event capture, annotation and analysis,

• Automatized data pipeline and client oriented applications,

• Research toward finding efficient algorithms for detection, classification and expertise, and real-time processing of the vast amount of data.

The progressive set up of the video data pipeline unveils three technical challenges:

• The challenge of having to serve multiple clients with different expectations and requirements: plasma operation agents focusing on standard events and requiring real-time reaction, wall maintenance clients needing long term monitoring and data accuracy, experimentalists striving to capture and process rare and potentially new events.

• The challenge of constituting an extensive, coherent and consistent cross machine database: wall health monitoring and wall incident language is still strongly device-dependent. The fusion communities have to converge toward common approaches and languages, especially in view of the upcoming ITER operation with international experimental teams.

• The challenge of data quantity and complexity: IR video data quantity is abundant (> TB per campaign) and still requires processing with time series from other diagnostic data for reaching a good expertise of the thermal events.

The challenges are described in the paper, along with the WEST team action path toward overcoming them.

[1] WEST operation with real time feed back control based on wall component temperature toward machine protection in a steady state, tungsten environment, Fusion Engineering and Design 165 (2021) 112223, R. Mitteau et Al.

| Country or International Organisation | France |

|---|---|

| Affiliation | CEA/Cadarache (IRFM) |