Speaker

Mr

Manfred Richter

(NUKEM Technologies Engineering Services GmbH)

Description

One pre-condition for Lithuania to join the European Union (EU) in 2004 was to shut down the Ignalina Nuclear Power Plant (INPP). The power plant has two RMBK type water cooled graphite moderated pressure tube reactors each of design capacity 1500MW(e) which started operation in 1983 respective in 1987. To fulfil this requirement, it was decided that Ignalina NPP several decommissioning projects had been initiated.

In January 2005 NUKEM Technologies GmbH in consortium with GNS mbH was awarded a contract for an Interim Spent Fuel Storage Facility (B1- ISFSF). As turn-key project the B1-ISFSF covers the design, procurement, manufacturing, supply, erection, installation, setting-to-work and commissioning.

Project Description

The INPP reactors were shut down for decommissioning by end 2004 respective 2009. Currently the spent fuel from the reactors is still stored in the cooling ponds. As for the decommissioning the reactor units have to be de-fuelled completely and approximately 18,000 fuel assemblies have to be stored, a new Interim Storage Facility has to be erected. In addition the scope includes also all necessary equipment for spent fuel retrieval, packaging, sealing, transport and other equipment appropriate to the design solution and required for the safe removal of the existing spent fuel from the storage ponds and insertion into the new ISFSF.

A small proportion of the spent fuel has suffered damage which is minor (without loss of integrity of the cladding) or major (potential for rupture of the cladding). It is necessary that this damaged fuel is also retrieved from the storage pools and stored in the new B1-ISFSF.

The following main design criteria for the new B1-ISFSF have be fulfilled:

- Interim Storage of spent fuel assemblies for at least 50 years

- Possibility of retrievability of spent fuel

- Two independent barriers to prevent the release of radioactive material to the environment, whereas the fuel cladding shall not be one of the barriers

- Criticality safety keff lesss than 0.95

- Nuclear and radiation safety in accordance with national and international standards

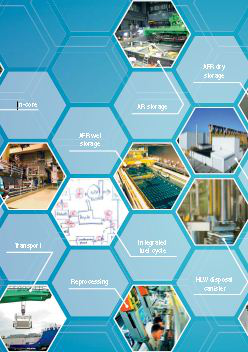

The main areas of the B1-ISFSF project are consisting of Fuel Bundle Handling and loading, Storage Casks Type CONSTOR® RBMK1500/M2, Damaged Fuel Handling System (DFHS), Casks Handling Equipment, transportation equipment, Interim Storage Building with infrastructure, Fuel Inspection Hot Cell (FIHC).

The presentation will describe the technical details, project challenges and actual status of the project.

Country/ int. organization

Germany

Primary author

Mr

Manfred Richter

(NUKEM Technologies Engineering Services GmbH)