Speaker

Dr

jean Desquines

(IRSN)

Description

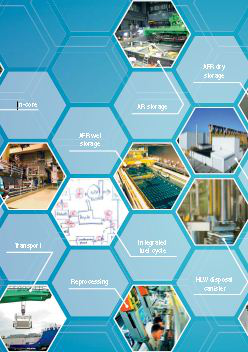

Considering the back end cycle, the transportation of spent fuel from reactors pools to storage pools at the reprocessing plant of La Hague in France might influence the zirconium based cladding strength, depending on the maximum temperature reached in the transportation cask. Fuel cladding corrosion during irradiation in reactor induces hydrogen charging with contents depending on fuel burnup. Part of this hydrogen is dissolved in the cladding during the transportation due to the higher temperature conditions. After transportation and during the fuel unloading in the storage pool, hydrides precipitate radially and this phenomenon strongly decreases the cladding ductility. IRSN has been involved since several years in the experimental characterization of the main process controlling the radial hydride precipitation. The thorough knowledge of this phenomenon is needed to assess safety analysis of wet or dry storages conducted by the licensee and to evaluate more specifically the consequences of drop loads scenarios in operation involving fuel assemblies.

A preliminary step in this study consisted in characterizing the influence of a constant applied stress to determine the stress thresholds controlling the orientation of precipitated zirconium hydrides. A new test technique was developed to study the influence of a broad range of temporally constant applied stresses using a single test. Pre-hydrided samples with hydrogen contents comprised between 10 to 600 wppm were studied. Three testing temperatures were studied: 350, 400 and 450°C and the results are used to adjust a model. The above mentioned test technique is not relevant to address the influence of time-varying stress level.

A modeling of decaying stress influence on radial hydride precipitation is derived from the results obtained for constant stress. Some new tests were performed with decreasing stress during the cladding cool down to provide validation data. The sample geometry of the tested pre-hydrided cladding consists in cladding rings with machined gage sections to test the influence of hoop stress. The radial hydride precipitation is quantified using post-test metallography combined with image analysis. The experimental results are compared to calculation results combining hydride diffusion and radial hydride precipitation modeling.

Country/ int. organization

France, IRSN

Author

Dr

jean Desquines

(IRSN)