Speaker

Dr

Valentin Ivanov

(Bochvar institute)

Description

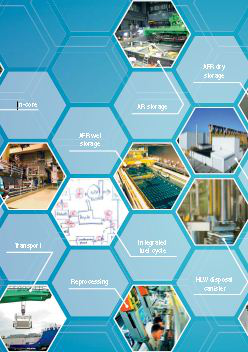

Success of closing of a nuclear fuel cycle (CNFC) is connected with the solution of the problem of the multiple recycling of actinides. One of the most promising options of closing NFC is a system with thermal reactors (TR) used uranium or mixed fuel and with fast reactors (FR) with high dense mixed fuel. Currently, in the RF various scenarios of closing NFC are considered, one of which is the reuse of plutonium, neptunium and possibly americium recovered from TR spent nuclear fuel (SNF) for fabrication of mixed nitride uranium-plutonium fuel (MNIT) for FR.

The developed scenario of CNFC, in addition to the safety, ecological and economic requirements, allows decreasing the risk of proliferation of weapon nuclear materials by eliminating the separation of plutonium during reprocessing; decreases the volume of stored plutonium; recycling not only uranium, plutonium and neptunium, but also transplutonium elements.

In given scenario of CNFC liquid metal coolant (lead or sodium) is used to safety assurance of FR, since in the case of accidents involving the loss of integrity of a primary cooling circuit with liquid metal the remaining heat removal is guaranteed. A lead option as one of the possible coolants leads to choice of MNIT fuel due to its high density, better compatibility fuel composition with coolant. Besides reactor with sodium coolant if using of MNIT seems to be in the best compliance with inherent safety demand too. Currently in Russia BR-1200 with sodium (BN-1200) and with lead (BREST-1200) coolant is being carried out. MNIT is the unified fuel for both reactors.

MNIT SNF reprocessing PH-process is being developed. PH-process is combined (pyro+hydro) technology based on non-aqueous operations, allowing the separation of actinides from fission products with coefficient purification 100-1000, and hydrometallurgical refining operations with total coefficient purification 1·106. PH-process allows reprocessing of FR SNF f with high burn-up and short cooling time; decreasing the volume of stored SNF and the amount of plutonium in CNFC; reprocessing of any type FR SNF; obtaining final uranium-plutonium-neptunium product purified for fuel refabrication using pellet technology.

At present time design of the pilot demonstration power complex with BREST-OD-300 reactor is started. The complex includes not only reactor but also fabrication and refabrication facility (2018 and 2024), reprocessing of SNF and waste treatment facility (2020).

Country/ int. organization

Russian Federation / Bochvar Institute

Primary author

Dr

Valentin Ivanov

(Bochvar institute)

Co-authors

Andrei Shadrin

(Bochvar Institute)

Mr

Mikhail Skupov

(Bochvar Institute)