Speaker

Dr

Juan Maria Garcia de la Infanta Belio

(Spent Fuel - Development and Equipments Technology - ENUSA Industrias Avanzadas)

Description

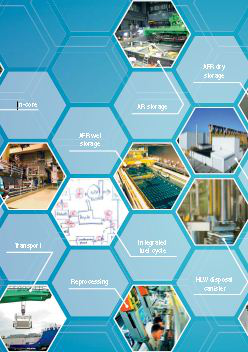

ENUSA, the Spanish nuclear fuel manufacturer since the 1980s, is the main specialist in Spain of LWR nuclear fuel design and performance. During this time, ENUSA has acquired deep knowledge and experience on the fuel assemblies burned by its customers, and currently stored in the spent fuel pools. Eventually, ENUSA has also specialized in spent fuel management, offering integrated engineering and on-site services to the Spanish plants. In fact, ENUSA currently has the lead in classification of spent fuel for dry storage and transportation projects developed in Spain.

Spanish spent nuclear fuel is classified following the US NRC legislation, particularly, the Interim Staff Guidance, ISG, 1 Rev. 2, which fixes the damaged fuel definition based on function. Along decades, fuel assembly design changes were focused on performance improvement to increase the end of life burnup and extend the fuel assembly useful life. However, not enough attention was paid on the impact of these changes and their consequences on the future spent fuel management.

Spent fuel management requires handling, drying, good behavior of the materials at higher temperatures, transportation, etc, at normal and accident conditions. The paper summarizes ENUSA’s PWR and BWR designs evolution identifying the main design features which have significantly impacted in the spent fuel management. Remarkable items are, for instance:

a)Old fuel rod designs with high initial internal pressure to avoid cladding collapse and short plenum lengths to compensate the irradiation growth. The lower volume and the high EOL internal pressures generate hoop stresses close to 90 MPa, stress limit according to ISG 11 Rev. 3, even after 30 years of cooling;

b)Stress corrosion cracking of top nozzle sleeves made of sensitized SS304 has caused handling limitations on thousands of PWR fuel assemblies, or

c)Zirconium oxide spalling of Zircaloy 4 fuel rods irradiated to high burnups has become a hot issue in spent fuel transportation and storage management due to local embrittlement of the cladding in the spalled areas.

Giving the impact of these particular issues in the spent fuel management, deep knowledge of the fuel assembly designs and the potential effects during spent fuel management are fundamental in order to accomplish a correct classification for dry storage and transportation. Moreover, since fuel assemblies design keeps continuous evolution to improve their performance and extend their useful life, the design process must analyze the impact of the design changes in the future back end.

Country/ int. organization

Spain/ENUSA Industrias Avanzadas

Primary author

Dr

Juan Maria Garcia de la Infanta Belio

(Spent Fuel - Development and Equipments Technology - ENUSA Industrias Avanzadas)

Co-author

Ms

Miriam Lloret

(ENUSA Industrias Avanzadas)