Speaker

Mr

Gerold Hermann Spykman

(TÜV NORD EnSys Hannover GmbH & Co. KG)

Description

Beside the long term behavior of the fuel itself the cladding behavior is an important issue for interim and long term storage of spent fuel in casks. In dry storage the fuel rod cladding is important for the retention of fission products. It is still the first barrier even if the storage casks are designed to contain the fission products during the designated storage period. In Germany the period for dry storage is limited today to 40 years starting with the loading of the cask. To ensure the cladding integrity the cladding hoop stress and the cladding hoop strain as well as the maximum temperature during drying and storage are limited to certain values. High burnup fuels as well as mixed oxide fuels have some properties that may be especially considered in dry storage with respect to cladding integrity especially when the storing time has to be extended. An extension of the dry interim storage time beyond 40 years might be necessary due to the lack of a final repository.

Both high burnup fuel and mixed oxide fuel has a higher fission gas release and a slower decrease of the post irradiation decay heat. Therefore, the number of high burnup or mixed oxide fuel assemblies is limited in most cask loading patterns. Further aspects of these kinds of fuel which should be addressed with respect to dry storage are the influence of the high burnup structure and the cavity pressure of the pores of the fuel. Whether these effects have an influence on fuel degradation and on the cladding integrity during the dry storage is not examined up to now.

The influence of high burnup or mixed oxide fuel on other cladding degradation mechanism like the inner and outer oxide layer, hydrogen pick up, irradiation damages in the cladding material crystal structure are well understood during fuel operation and pool storage, but the long term consequences still aren’t verified due to the lack of experience and long term experiments.

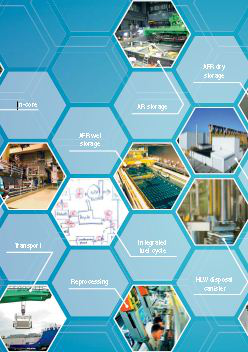

One approach to consider these effects in future is to extend existing fuel performance codes with appropriate models and the consideration of all stages of the fuel life from the more short term operational behavior to the long term storage time. Within such assessments conservative as well as best estimate approaches should be considered. For long term predictions deterministic and probabilistic methods should be used in parallel.

Country/ int. organization

Germany

Author

Mr

Gerold Hermann Spykman

(TÜV NORD EnSys Hannover GmbH & Co. KG)