Speaker

Mr

Tatsuya Ishikawa

(Recyclable-Fuel Storage Company)

Description

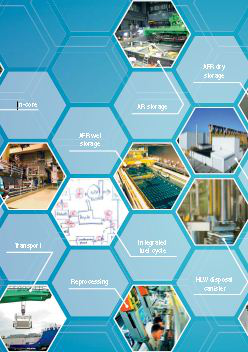

Recyclable-Fuel Storage Company (RFS) has completed construction works of the storage building and fabrication works of several metal casks for spent fuels as the Japanese first off-site interim storage operator. RFS are now undertaking the safety review under new regulation standards based on the lesson learned by Fukushima-daiichi accident and preparing for the start of operation.

This paper introduces the outline of the design and construction work experience for this facility.

This interim storage facility is intended to temporarily store the spent nuclear fuels of light water reactors till they are reprocessed. The building has a storage capacity of up to 288 dry metal casks. The storage building has natural air cooling systems for removing heat from the filled casks. The center part of the storage area has high-height exhausting part for effective ventilation. On the other hand, the other part of the storage area has low-height ceiling because metal casks are moved by the air pallet transporter instead of overhead crane.

Metal casks are designed so that the basic safety feature of the casks such as containment, shielding, subcriticality and heat removal are safely maintained during storage periods of 50 years. Negative pressure is kept for inner part of casks and positive pressure is kept for the part between two lids. The casks are also filled with helium gas so as to convey heat effectively and to maintain the fuel integrity. These casks are used for dual purpose i.e. both storage and transport. For transport, tertiary lid and impact limiters are also set on the casks. During storage, visual inspection, pressure monitoring between the double lids, temperature checking on the casks and monitoring of radiation dose of inner storage building, etc. are carried out.

The establishment permit for spent fuel storage and approval of design and construction methods were issued in 2010. After the approval, RFS started the construction of the spent fuel storage facilities. Construction works of storage building including installation of the electrical and mechanical equipment were completed in August 2013. Fabrication of several metal casks was also completed with various inspections as transport and storage casks.

Currently, RFS has been undertaking NRA review under new regulation standards. As preparation work for the start of the operation, RFS carried out the training of the handling casks using mock-up cask, air pallet transporter, handling equipment and transport vehicle.

Country/ int. organization

Japan

Primary author

Mr

Masahiko Takahashi

(Recyclable-Fuel Storage Company)

Co-authors

Mr

Hideyuki Chikahata

(Recyclable-Fuel Storage Company)

Mr

Tatsuya Ishikawa

(Recyclable-Fuel Storage Company)