Speaker

Ms

Vanessa Vo Van

(AREVA NC)

Description

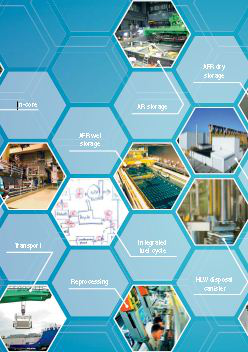

Defective fuel management is a major challenge for nuclear operators when time comes up for finding a long-term solution for all their used fuel assemblies, defective included.

Managing the defective fuel assemblies indeed requires implementation of specific technical solutions.

Reprocessing the defective fuel assemblies is the most decisive way to get rid of them: there is then no need to assess the behavior of this specific type of fuel assemblies in the long-term. Defective fuel assemblies are being today safely transported to and reprocessed in a treatment plant.

When reprocessing is not the preferred option, the nuclear operator must choose between two dry storage solutions for the defective fuel assemblies: interim or long-term.

This paper describes the existing solutions for transportation and dry storage of defective fuel assemblies.

Transportation of defective fuel assemblies is today being performed. Various cask designs exist for that purpose and specific operations are implemented for preparing the defective fuel assemblies for transport. The advantage of such solutions is that they can support the operator in getting rid of the defective fuel assemblies once and for all.

The paper presents the operational experience, the new licensing methodology relative to transport of defective fuel rods.

Interim dry storage of defective fuel assemblies has been implemented for decades in the USA. Specific operations are performed for preparing the defective fuel assemblies which are then stored along with intact spent fuel assemblies in the dry storage cask. The advantage of such a solution is its short-term cost effectiveness.

The paper presents the existing dry interim storage solutions for defective fuel assemblies, the associated operational experience.

A long-term dry storage solution for defective fuel assemblies is being developed, compliant with direct disposal safety requirements. The solution is based on the dry encapsulation of each defective fuel rod into a fuel rod capsule, followed by its transfer into a capsule canister (like a fuel assembly skeleton), which is replacing a fuel assembly position of the transport and storage cask, and the associated specific licensing approach: this is the best available technology regarding long-term storage safety requirements.

The paper presents this unique capsule technology, the transport and storage casks that can be used for transportation of defective fuel rods to the storage facility and especially focusses on the associated robust safety demonstrations that support the transport and storage licensing approach currently used in Europe.

Country/ int. organization

France / AREVA

Primary author

Ms

Vanessa Vo Van

(AREVA NC)