Speaker

Description

The Russian concept of steady-state operating plasma-facing components (PFC) based on the use of a stagnant or slowly flowing liquid metal (LM) as a plasma-facing material enclosed in a capillary-porous system (CPS) (Ref. 1) integrates all the advantages of LM with the possibility of uniform distribution of its layer on the surface, regardless of its orientation in space, with high resistance to splashing under electromagnetic force. Heat removal is provided by thermal conductivity through the PFC structure to the flowing coolant. Thus, the ability of a CPS-based PFC to withstand high-density stationary heat flux and not pollute the plasma strongly depends on the selection of design, materials and coolant. The first experience in creation of such limiter type PFC with a LM and an active surface temperature stabilization system were successfully implemented for T-11M and FTU tokamaks (Ref. 2).

The development program for liquid metal PFCs, including the creation and model testing of prototypes, is aimed at solving the following key tasks: 1 - providing continuous refilling and even distribution of LM on the CPS surface; 2 - achieve periodical replacement of liquid metal (in particular lithium) in the CPS structure with the aim to decrease of the concentration of dissolved tritium; 3 - study the ability of LM surface cleaning from the deposited films and products of interaction of LM with the residual gases through a providing of LM flow on the surface and in the structure of CPS; 4 - development of design and operation parameters definition for the LM supply systems; 5 - study of the process of removal of energy flux of high density from the PFC surface; 6 - development of design and operation parameters definition for the systems of effective heat exhaust. Solving these problems will allow creating reliable and capable PFC for a stationary tokamak reactor.

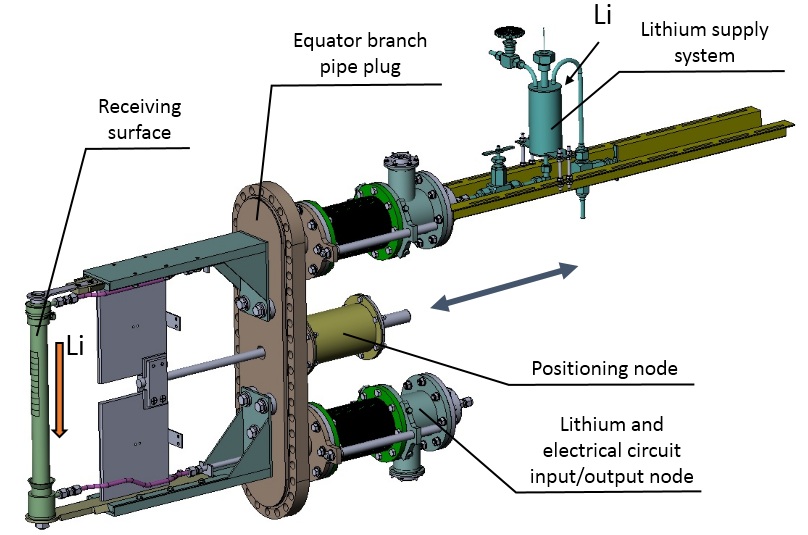

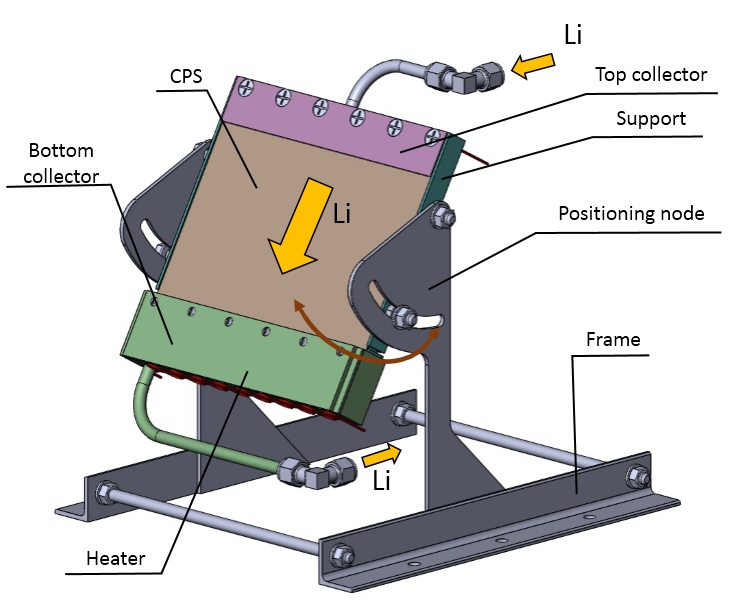

The solution of the problems according to program points 1-4 is achieved by studying the created prototypes of the lithium limiter of T-11M (Fig.1) and the mockup of the lithium divertor target of T-15MD (Fig.2) both in the conditions of the vacuum pilot facility and in the conditions of the tokamak. Both prototypes consist of an internal part and an external liquid lithium supply/replacement system (Fig.3). The in-vessel elements of the prototypes, whose plasma-facing surfaces (cylindrical for T-11M and flat for T-15MD) are made of stainless steel and covered with a layer of CPS made of molybdenum mesh, are equipped with an upper collector for liquid lithium supply and distribution and a lower collector for LM lead out. The maintenance of lithium in the liquid state is provided by an electric heater. The mockup of the divertor target allows to change the angle of inclination of the plasma facing surface to the horizon within 30-90o. The refilling, retention and uniform distribution of lithium on the plasma-facing surface are due to capillary forces in the CPS structure. When an excessive amount of LM is fed to the upper collector, it slowly drifts in the CPS structure under the gravity to the lower collector. Cleaning the surface of the CPS from films of lithium reaction products with residual gases and deposited materials realized by the flow of LM on the surface of the CPS with an excess of LM supplied to the upper collector.

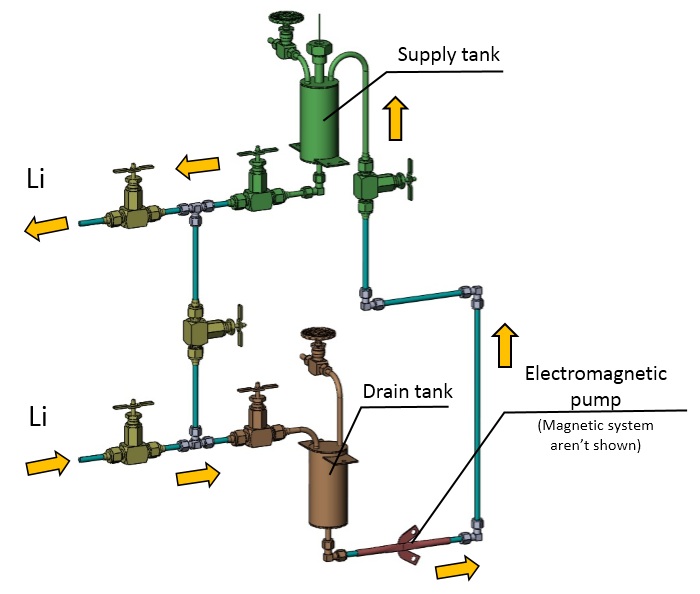

Liquid lithium supply and discharge tubes connect the prototype of in-vessel element to the external lithium supply / replacement system. The supply of lithium to the PFC is carried out under the effect of the hydrostatic pressure of the lithium column in the supply tank or by creating an excess pressure of lithium in the tank by supplying argon gas. The lithium stream leaving the PFC enters the drain tank and returns to the supply tank using an electromagnetic pump. The system provides a wide range of experimental possibilities for organizing the supply and replacement of lithium and is additionally equipped with measurement, monitoring and service elements. The first experiments with liquid lithium limiter of T-11M tokamak in pilot facility demonstrated the possibility of creating a uniformly distributed flow of lithium both in the structure and on the surface of the CPS. The rate of Li exchange in the CPS was ~0.4 cm3/s and the surface flow rate was ~ 1 cm/s, which was determined by the change in the level of LM in the supply tank and visually by the speed of the special marker on flowing surface respectively.

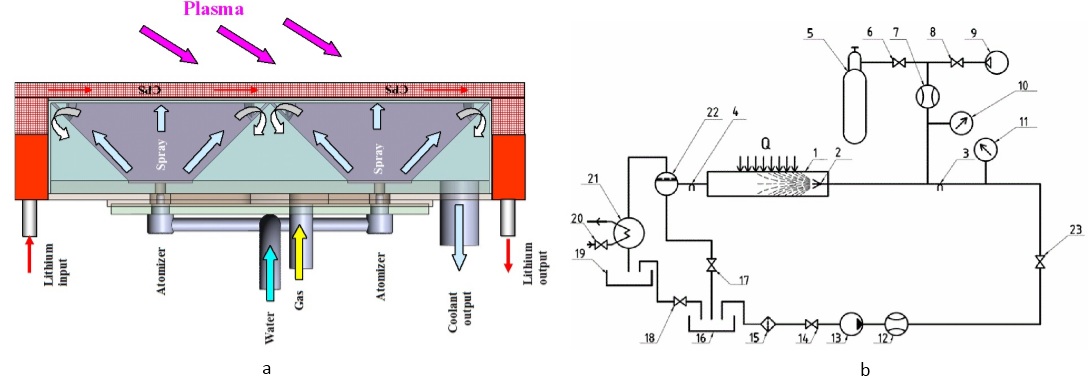

The problems in program points 5 and 6 are solved using thermal model (Fig.4), providing a study of the process of cooling the PFC at heat flux in the range of 1-15 MW/m2 in the modeling conditions of the experimental facility. The thermal load on the mockup surface is applied using a scanning electron beam. Heat removal from the heat receiving surface of the model is provided by evaporation of water droplets coming to the inner side of the receiving wall with a gas-drop stream generated by the atomizer (Ref. 3). The operation of the atomizer is provided by the system for supplying the coolant components (air, water) at various adjustable values of pressure (0.1-0.3 MPa) and flow rate (for water of 0-250 l/h; for air - 0-10 Nm3/h). The evaluation of the heat exhaust efficiency is controlled by the value of the receiving surface temperature and using a calorimeter. Experiments are conducted starting from the end of 2017. To date, it has been found that at power flux up to 12 MW/m2 the effective heat removal is provided at a coolant pressure not higher than 0.2 MPa with a heat transfer coefficient of 70-100 kW/m2K. Thermal model to study the process of heat transfer with the coolant flowing perpendicular to the cooling wall was developed and prepared for testing in 2020-2021.

The results of creation and tests of the prototypes and models made it possible to develop and justify the design of the complex steady-state operating lithium limiter of the tokamak T-15MD, ensuring the implementation of a closed circuit of atoms of lithium in the tokamak chamber without it uncontrolled accumulation, to optimize the operating parameters of the cooling system and properties of gas-water coolant.

- Evtikhin V.A., Lyublinski I.E., A.V. Vertkov, et al., Liquid Lithium Tokamak Reactor, Fusion Energy 1996 (Proc. 16th IAEA Conf. on Fusion Energy, Montreal, 1996). Vol. 3, IAEA, Vienna (1997) 659-665.

- Vertkov A., Lyublinski I., et al., Experience in the development of liquid metal plasma facing elements based on capillary-porous structures for a steady-state tokamak (survey). — Physics of Atomic Nuclei, 2018, vol. 81, № 7, p. 1000—1007.

- S.V. Mirnov, A.T. Komov , A. N. Varava et al., Features of heat transfer with cooling by dispersed flow, Now. 2019, Journal of Physics Conference Series 1370:012002 DOI10.1088/1742-6596/1370/1/012002.

| Affiliation | SC "Red Star" |

|---|---|

| Country or International Organization | Russia |